New ceramic nanotubes could prolong aircraft engine coatings by controlling high-temperature heat radiation. Idha Valeur reports.

In an attempt to increase the lifetime of ceramic coatings used for gas turbines in aircrafts, researchers have developed a new material that can control the engine’s heat radiation.

The material, a polaritonic ceramic, combines high-temperature properties of ceramics with the functionality of polaritons. To do this, the team developed a polaritonic ceramic coating to make high-temperature thermal antennae and claimed this offered control over the spectrum and direction of high-temperature heat radiation. Purdue University PhD student, Xueji Wang, explained that their theoretical work suggested that hexagonal boron nitride (hBN), a polaritonic ceramic material that is stable at high temperatures, has unique thermal emission characteristics. ‘But the unique thermal emission of bulk hBN material is confined to the near field, up to 1um away from the material surface,’ Wang told Materials World.

‘We found multi-walled boron nitride nanotubes (BNNT), which share the similar polaritonic properties and high-temperature stability of hBN and also show antenna effects to couple the nearfield dark modes into far-field thermal radiation. We designed the device structure, developed the drop coating method and finally got this BNNT thermal emitter.’

When using the drop coating method, commercial BNNT powders are dispersed into an ethanol solvent, Wang said. ‘Then the BNNTcontaining ethanol is dropped on to a 300nm tungsten thin film on a polished silicon wafer with pipettes. After ethanol volatilised, the BNNTs form a disordered film and coat on the tungsten surface. ‘All these steps can be done in less than one hour regardless of the size of the substrate.’

Expressing the importance of this progression, Purdue University, USA, Associate Professor of electrical and computer engineering and team leader, Zubin Jacob, told Materials World that hBN and BNNTs produce the highest optical phonon frequency of all known materials, hence extending the scope of the material database for mid-infrared thermal engineering. He added that the boron nitride ceramic nanotube coating shows high thermal stability at temperatures up to 938K, which makes them suitable for applications in extreme environments such as power generators and aircraft engines.

According to Wang, the team demonstrated its stability by heating it and measuring the thermal emission signal. They did this using a self-made thermal emission spectroscopy set up, which showed no significant degradation. This indicated that the BNNT coatings are thermally stable. ‘Finally, the BNNTs are natural ceramic antennas. Compared with other methods for thermal radiation control, such as artificial thermal metasurfaces or photonic crystals, this BNNT coating doesn’t require any complicated fabrication techniques and is extremely easy for large-scale production,’ Jacob said.

Wang added that the reason the BNNT coating is easy to scale up is because it does not require nanolithography processes, which often require vast amounts of cleanroom work and expensive tools. ‘Thus, compared with other nano-structured thermal emitters, this BNNT coating is more suitable for large-scale production,’ he said.

According to Jacob, thermal radiation is generally considered to be omnidirectional with a broad spectre, but that the radiation from their nanotube emitters has three narrow bands – all at different wavelengths. ‘These three emission bands also show some angular dependence. This is very different from the thermal radiation of usual object and materials but is very similar to the emission pattern of antennas,’ he said. ‘This is achieved by the novel light-matter interactions – phonon polaritons – in the unique 1D structure of BNNTs.’

Moving forward

Currently, the team is looking at other properties of hBN and BNNTs that could be of interest and attempting to create other novel systems to control thermal radiation. ‘We are also trying to find more polaritonic ceramics that are suitable for thermal radiation control’, Jacob said.

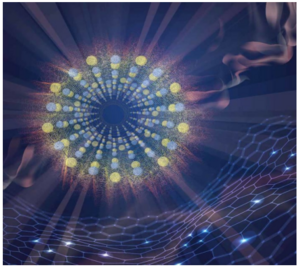

An illustration of the BNNT and thermal radiation. Credit: Purdue University Illustration/Xueji Wang