Manufacturers frequently use coatings to protect the structural stability of engines or power generators operating at high temperatures. Ceramic shields, however, have not been able to adequately address a critical, performance-limiting factor: heat radiation.

Researchers have engineered ceramic nanotubes (shown in yellow). The nanotubes act as antennas, which use light-matter oscillations to control heat radiation. The design is a step toward a new class of ceramics that work more efficiently at high temperatures. (Purdue University illustration/Xueji Wang.

A new ceramic coating from Purdue University acts as a kind of thermal antenna, using lightmatter oscillations, or polaritrons, to control the direction and electromagnetic spectrum of thermal radiation. According to the researchers, including Purdue professor Zubin Jacob, the design is a step toward a new class of ceramics that work more efficiently at high temperatures.

“These nanotubes work as a system of hightemperature ceramic antenna emitters, creating strong mid-infrared thermal emission and distinct spectral and spatial thermal emission patterns,” Zubin Jacob told Tech Briefs.

The team built the nanotubes built nanotubes from an emerging ceramic material known for its high thermal stability: hexagonal boron nitride. The ability to control radiation occurs when the boron nitride becomes a cylinder. In cylindrical form, boron nitride nanotubes (BNNTs) possess subwavelength oscillations capable of coupling to heat radiation.

The coating’s hexagonal boron nitride, or hBN, contains part-light, part-matter quasiparticles known as polaritrons. When excited by high temperatures, the nanotubes, acting as antennas, bind the polaritrons to the outgoing energy.

The 1 x 1 cm mid-IR thermal antenna emitters, made from the high-frequency optical phonons present in the boron nanotubes, operate at temperatures as high as 938 K. The multi-walled BNNTs are of an average diameter of 50 nm and lengths of 5−20 μm.

With further design efforts, the radiative engineering effect of the BNNT thin film presents a pair of engine-performance benefits, according to the Purdue professor of electrical and computer engineering. “By controlling radiation at these high temperatures, we can increase the lifetime of the coating,” said Jacob. “The performance of the engine would also increase because it could be kept hotter with more isolation for longer periods of time.”

In an interview with Tech Briefs below, Jacob reveals what other applications are possible when you can take control of thermal radiation.

Tech Briefs: What did you create exactly?

Zubin Jacob: We have developed a polaritonic ceramic. This is a fundamentally new class of materials that combines high-temperature properties of ceramics and adds the functionality of “polaritons.” Polaritons are collective light-matter oscillations which are thermally excited at high temperatures.

We developed a disordered multi-walled boron nitride nanotube (BNNT) system by drop-coating BNNT powders on tungsten thin films. These nanotubes work as a system of high-temperature ceramic antenna emitters, creating strong midinfrared thermal emission and distinct spectral and spatial thermal emission patterns.

Tech Briefs: How does the BNNT system work?

Zubin Jacob: Hexagonal boron nitride (hBN) is a 2D material with a unique set of optical properties. The phonon polariton resonances and hyperbolic anisotropy of hBN create strong near-field radiation at elevated temperatures. By rolling sheets of hBN into a tubular geometry, we can form subwavelength particles (BNNTs), which can couple these near-field dark modes to the thermal radiation in the far-field.

Tech Briefs: Why is this achievement an important one?

Zubin Jacob: First of all, hBN and BNNTs produce the highest optical phonon frequency among all known materials, which extend the scope of the material database for mid-infrared thermal engineering.

Secondly, these boron nitride ceramic nanotube coatings show high thermal stability, which enables their application in extreme environments including high-temperature power generators and aircraft engines.

Finally, the BNNTs are natural ceramic antennas. Compared with other methods for thermal radiation control, such as artificial thermal metasurfaces or photonic crystals, this BNNT coating doesn’t require any complicated fabrication techniques and is extremely easy for large-scale production. This simple disordered BNNT system can also withstand higher temperatures than other nano-structured thermal emitters.

Tech Briefs: How do the nanotubes control radiation?

Zubin Jacob: Generally, thermal radiation is considered to be omnidirectional and spectrally broad. However, the thermal radiation from our ceramic nanotube emitters has three narrow emission bands at different wavelengths. These three emission bands also show specific angular dependence. This is very different from the thermal radiation of usual objects/materials but is very similar to the emission pattern of antennas. This is achieved by the novel light-matter interactions (phonon polaritons) in the unique 1D structure of BNNTs.

Tech Briefs: Have you tried to create similar metamaterials?

Zubin Jacob: We have some other works in which we use different materials to engineer thermal emission.

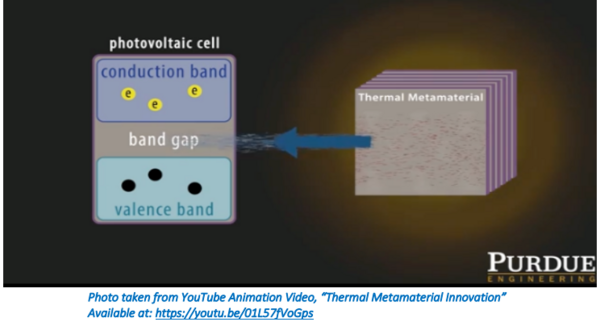

In 2016, we developed a thermal metamaterial that is made of a multi-layer stack of tungsten and hafnium oxide. This thermal metamaterial was designed to enhance a specific spectral range of the thermal radiation that can be absorbed by photovoltaic cells and suppress the thermal radiation at other wavelengths. This metamaterial shows high-thermal stability up to 1000 °C. It can be used in thermophotovoltaic cells to utilize waste heat harvested from power plants and factories.

(Nature Communications volume 7, 11809, 2016)

In 2018, we also created a bi-periodic grating emitter using silicon carbide and achieved a dualband thermal radiation control. This silicon carbide emitter is stable at temperatures up to 1000 K.

(Journal of Quantitative Spectroscopy and Radiative Transfer, 216, 99-104, 2018)

Tech Briefs: What needs to happen to commercialize the material that you most recently developed?

Zubin Jacob: We need to find the proper approach to large-scale production and integration.

Additionally, we are studying other interesting properties of hBN and BNNTs and trying to create some other novel systems to control thermal radiation. We are also trying to find more polaritonic ceramics that are suitable for thermal radiation control.