The innovative metal-silicide–based coatings, selected for the front cover of Advanced Optical Materials, promise to revolutionize heat management in extreme environments.

Image caption: The image illustrates the concept of Thermal Dual-Barrier Coatings (TDBCs), where metal-silicide metamaterials embedded in ceramics act as a shield between fire and ice—reflecting radiant heat while blocking conduction. The research, led by Prof. Zubin Jacob and Dr. Avra Bandyopadhyay, has been selected for the front cover of Advanced Optical Materials, recognizing their breakthrough in high-temperature thermal management.

Researchers at Purdue University developed a groundbreaking class of thermal barrier coatings that uses metamaterial principles to withstand extreme temperatures while suppressing both heat conduction and radiation. The work, published in Advanced Optical Materials (https://doi.org/10.1002/adom.202501827 ) and to-be-featured on the front cover of the journal, represents a paradigm shift in how materials can be engineered to survive in the world’s hottest environments: from jet engines to next-generation energy systems.

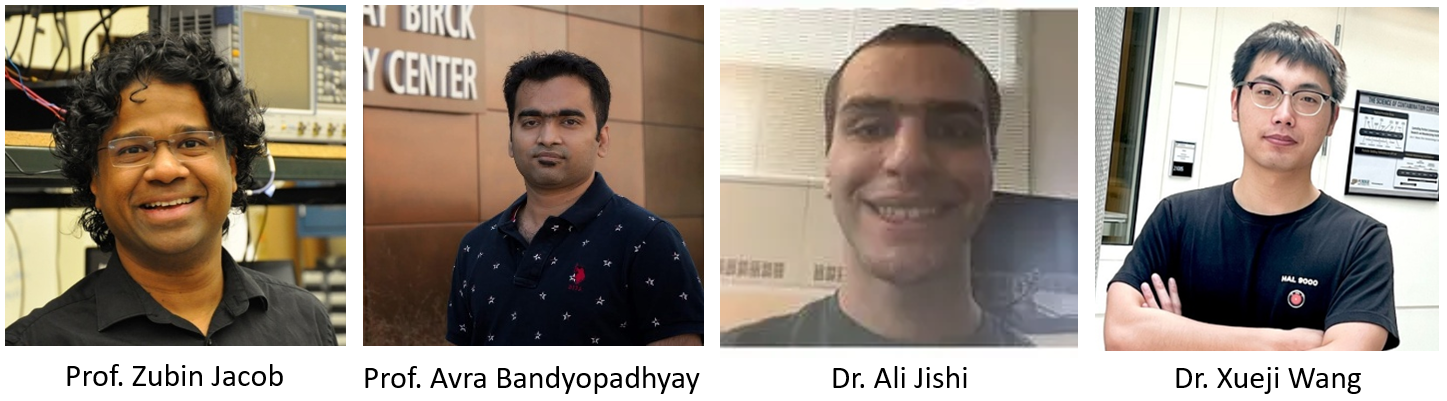

Led by Prof. Zubin Jacob (Elmore Professor of Electrical and Computer Engineering at Purdue University) and Dr. Avra Bandyopadhyay (currently an Assistant Professor of Electrical Engineering at Prairie View A&M University), the research introduces Thermal Dual-Barrier Coatings (TDBCs), a novel concept that combines low-conductivity ceramics with high-temperature reflective metal silicides to block both phonon and photon heat transfer.

“For decades, engineers have focused on minimizing only thermal conduction,” Jacob said. “But at turbine operating temperatures above 1000°C, radiative heat transfer dominates -- and traditional porous ceramics cannot stop it. Our work unites thermal and optical physics to design coatings that reflect heat like a mirror while remaining mechanically robust.”

The innovation lies in embedding ultra-subwavelength metal silicide layers inside a conventional yttria-stabilized zirconia (YSZ) matrix. These reflective layers form a metamaterial that suppresses radiative heat transport across a broad spectrum, effectively “taming the light” within the coating.

Dr. Bandyopadhyay spearheaded the experimental development of the TDBC system during his postdoctoral research at Purdue, focusing on integrating metal-silicide nanolayers into ceramic coatings capable of withstanding extreme environments. He led a team of graduate researchers, including Ali Jishi and Xueji Wang, who made significant contributions to both experimental and theoretical efforts. Ali and Xueji were instrumental in bridging the design-to-demonstration gap—setting up the experimental testbeds, performing high-temperature annealing and optical characterization, and developing the simulation models that guided the coating architecture. Their combined work enabled precise correlation between predicted performance and measured results, ensuring the metamaterial concept could be successfully realized in practice.

“Gas turbines and hypersonic vehicles face extreme environments where both conduction and radiation are intense,” Bandyopadhyay said. “Our design achieves a 20 Kelvin improvement in the temperature gradient across the coating -- potentially translating to higher engine efficiency, longer component lifetime, and reduced fuel consumption.”

“We are thrilled to see this work will be featured on the front cover of Advanced Optical Materials,” Bandyopadhyay added. “It represents not only a new frontier in thermal management but also a vision for sustainable, high-temperature materials that merge optics, materials science, and energy efficiency.”

This research was supported by the Defense Advanced Research Projects Agency (DARPA) and carried out in collaboration with Purdue’s Birck Nanotechnology Center. This work has also led to a U.S. Patent (US 11,971,226 B2) titled High Temperature Thermal Dual-Barrier Coating, underscoring its translational potential for future industrial applications. These findings are expected to influence material design for aerospace propulsion, clean energy systems, and next-generation semiconductor manufacturing, where extreme temperature resilience is critical.

Read it online: https://doi.org/10.1002/adom.202501827